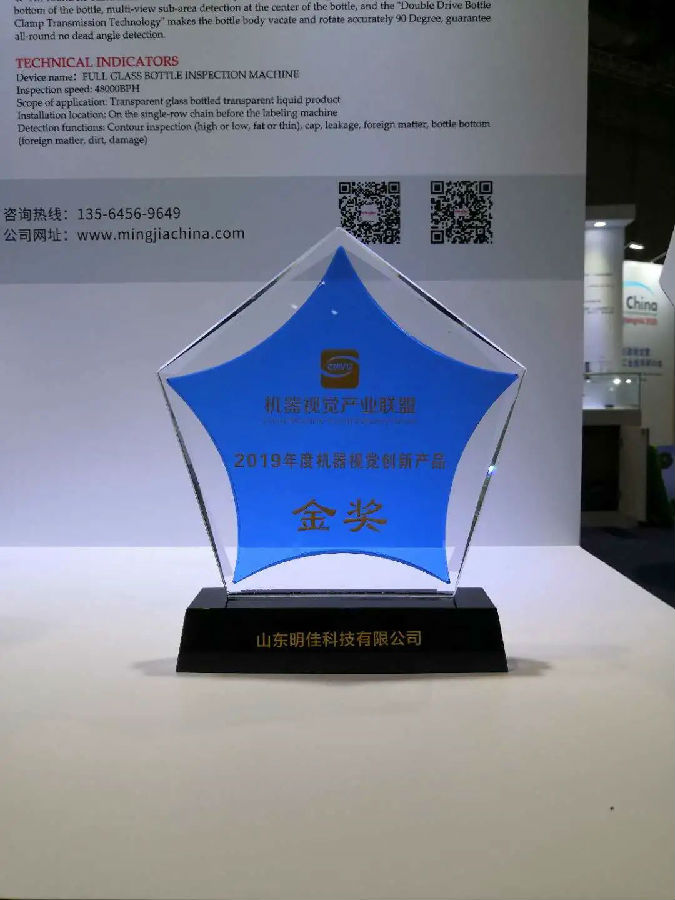

On July 5th, VisionChina (Shanghai) successfully concluded in National Convention and Exhibition Center (Shanghai)! This exhibition, Mingjia technology with the company's "star" product - glass bottle filling finished product testing machine appeared in the exhibition, and in-depth discussion with industry experts from all over the future development trend, to bring new products, new solutions for the audience zero-distance experience. In addition, the equipment of Mingjia Technology won the Gold Award of "2019 Annual Machine Vision Innovative Products" by the Machine Vision Industry Alliance (CMVU)!

Ming jia finished beer testing machine is the company independent research and development of the domestic first with multiple points of view, transfer, and multi-function testing machine not only has high efficiency, fast speed, high precision, the characteristics of reliability, is based on the actual situation, the domestic beer industry relative to foreign brands of bottle source site environment required in "the water", Mingjia finished wine testing machine on the function of local enterprises more adaptable, compatibility; At the same time, the cost performance is high, can at least replace the lamp inspection position 5 artificial; It also has the advantages of short supply cycle and strong after-sales service guarantee.

Equipment is introduced

Product wine foreign body detection machine using machine vision, sound detection and other detection methods, an overall inspection for finished product of bottling wine needs, can be the bottleneck, bottle shoulder, side wall and bottom of the bottle, the bottle more precision detection area, can detect including height, liquid level height, gas leak, wine in the dirt all sorts of defects, such as foreign body, the bottle and online. It can significantly improve the reliability of the testing link after filling, and greatly reduce the number of workers and labor intensity.

Technical characteristics

1. One-key bottle type switch: the equipment automatically lifts and adjusts, bottle type switch is automatically completed without manual adjustment, bottle type adjustment is quick and simple, avoiding the difference of manual adjustment;

2. Targeted design of detection module: Targeted design of detection module for various typical defects of finished wine. In addition to the conventional detection function, it can ensure that foreign bodies in the wine are difficult to be found by light inspection, such as precipitation in the wine body and smudginess in the bottle shoulder pattern area, and can still be accurately detected;

3. Automatic multi-spectral imaging: can automatically adjust the light source spectrum according to the bottle type, to achieve the highest contrast, the recognition accuracy is significantly improved;

4. Omni-directional detection without blind area: multi-angle sub-area detection of bottle body, bottle shoulder, bottle bottom outer edge, bottle bottom anti-skid pattern, bottle bottom center. With the "double drive bottle clamping drive mechanism technology", the bottle body is stably suspended and rotates 90 degrees accurately to ensure omni-directional detection without dead Angle;

Technical indicators

Detection speed: 48000 containers/hour

Scope of application: transparent liquid products in transparent glass bottles

Installation location: on the single row of chain before the labeling machine

Detection function: bottle into detection (high and short bottles, fat and thin bottles), cap detection, leak detection, foreign body detection, bottle bottom detection (bottle bottom foreign body, dirty, damaged)