As the VisionChina2023 (Beijing) exhibition approaches, the machine vision organizing committee, exhibition exhibitors, and speakers are all working hard to prepare. On such a special day, let's invite Ma Ji, the regional sales manager of Shenzhen LightE-Technology Co., Ltd., to guest at "Vision Dialogue · Exhibitor" to listen to his views on the current situation of the domestic machine vision industry and his expectations for this Beijing conference.

Q: What products, technologies, and solutions will your company bring to the VisionChina (Beijing) 2023 exhibition? What are the highlights? What are the landing application cases of these display products?

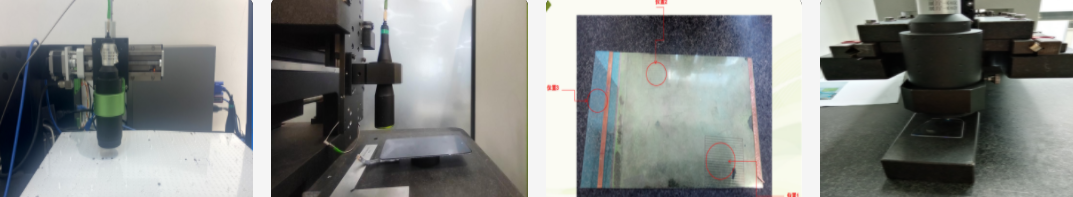

A: The product we bring to this exhibition is a spectral confocal displacement sensor. Our company is the first high-tech company in China to have mass production technology for this sensor, both of which are replacing foreign monopolies in the market and filling the market gap. This technology can help our customers improve the detection accuracy of their equipment. Our product has a resolution of up to 1 nanometer, breaking through the technical blockade of foreign brands, and is committed to providing Chinese industry, materials, and machinery, Provide cutting-edge detection technology solutions in fields such as semiconductors, medicine, automobiles, pharmaceuticals, and aerospace.

The sensor material has a wide adaptability, making it easy to measure the mirror surface, curved or tilted mirror surface, rough surface, transparency, droplet surface, etc; Capable of measuring complex shapes of targets without blind areas for triangulation, capable of measuring complex shapes; High precision, based on wavelength measurement of light waves, with a resolution of up to nanometer level and good anti-interference; Measuring the small size of the light spot and being able to distinguish small contours; Good temperature stability, the lens itself does not generate heat, and the temperature drift is small.

application

Assist in measuring the thickness, flatness, etching depth, and groove depth of third-generation semiconductor materials such as silicon wafers, germanium, silicon carbide, and gallium nitride in the core components of semiconductor equipment.

In the new energy industry, measurements of battery electrode thickness, diaphragm thickness, soft pack battery thickness, and blade battery size can be carried out.

In the 3C industry, mobile phones, tablets, computer cameras, middle frames, hardware and plastic components, 3D glass, and other segment differences, steps, blade patterns, assembly positioning, thickness, roughness, flatness, contour measurement, LCD panels, OLED, MiniLED, microED devices, film, foil, glass, graphene, and other related cases continue to be implemented.

Q: What are your thoughts on the newly proposed "Outline for Building a Strong Quality Country" this year? What role has machine vision played in promoting the orderly implementation of the quality strengthening strategy?

A: If the quality is strong, the country will be strong, and if the quality is prosperous, the country will be prosperous. The continuous improvement of quality level can only demonstrate the power of a strong country by creating higher standards and high-performance products. 3D industrial vision uses the "machine eye" to replace the human eye, achieving recognition, measurement, and making judgments such as guidance and detection. Machine vision has high perception efficiency and accuracy, and can achieve unmanned operation in industrial scenes, which is the core technology of Industry 4.0. Machine vision plays a crucial role in inspection equipment, with the support of core inspection technology, allowing the quality of various products in our country to reach a higher level.

Q: How does your company cater to the development of current innovative technologies, such as edge computing, artificial intelligence, deep learning, embedded vision, 5G+, and so on? What is the next technological direction that needs efforts and breakthroughs?

A: In the next step, our company will mainly focus on high-end machine vision sensors. Under the influence of multiple factors such as policies, demand, scenarios, domestic substitution, and machine substitution, industrial vision is expected to have a compound growth rate of 25% in the next five years, and the market size will reach 54.3 billion yuan in 2026. The core sensor market size of 3D industrial vision is also in the tens of billions level. Technological iteration and domestic substitution have strong driving force, and spectral confocal technology is mainly used in precision detection scenarios, which can solve the bottleneck problem of traditional laser methods and is recognized as a mainstream technology in the future. The current market is mainly monopolized by some foreign enterprises, and more than 90% of the products used in the technical solution rely on imports, which is a bottleneck technology, with huge domestic substitution space. Our company is constantly making breakthroughs in technology. In order to better improve the detection level, we will continue to invest in research and development, and develop higher precision products, such as line confocal sensors, interference sensors, etc. To meet the needs of higher detection equipment. Especially for semiconductor related testing equipment.

Q: In the next few years, do you think there will be growth or new market demand for machine vision applications in the Chinese market and globally? What segmented areas will the company focus on in the next step?

A: With the changes in the international environment, new energy, semiconductors, and military industries have become the most highly regarded sub sectors in China. These three industries are very active in technological innovation, industrial upgrading, and pattern optimization, and there are intersections among them that can catalyze each other, constantly forming new directions and opportunities. Our company believes that they will be in line with the development direction of our product market. In the future, our company will focus on laying out key development layouts in the areas of new energy photovoltaic testing equipment, lithium battery industry testing equipment, semiconductor and other industry testing equipment.

Welcome to visit the booth of Shenzhen LightE-Technology Co., Ltd.

Booth number: A10