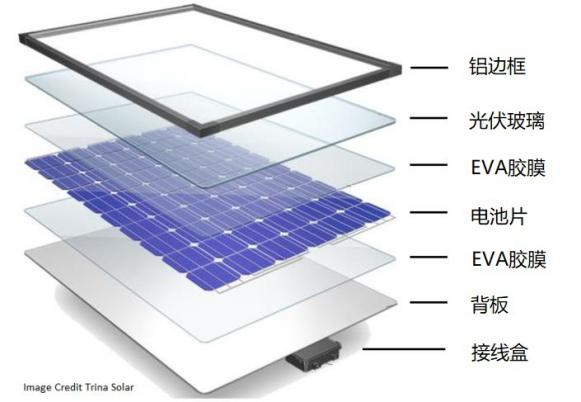

Photovoltaic glass is a kind of flat glass produced by calendering method. It is one of the most important parts of solar cell module. Photovoltaic glass in the production process will inevitably produce common defects such as: bubbles, bubble, stone, crystallization line, etc.. In order to ensure the light transmittance, strength, safety and other requirements, the defect detection of photovoltaic glass should be carried out before leaving the factory to prevent the inflow of defective products into the module production process causing resource loss.

Photovoltaic glass factory inspection methods can be divided into manual inspection and equipment inspection two ways. Is artificial detection methods used by most manufacturers, as labor costs increase year by year, at the same time, low efficiency of manual inspection, can not guarantee the consistency of the test results as a result, more and more manufacturers begin to try equipment detection scheme, stable, accurate and efficient photovoltaic glass surface online testing equipment has become the preferred manufacturers. Photovoltaic glass manufacturers are in urgent need of equipment that can realize automatic and high precision visual inspection.

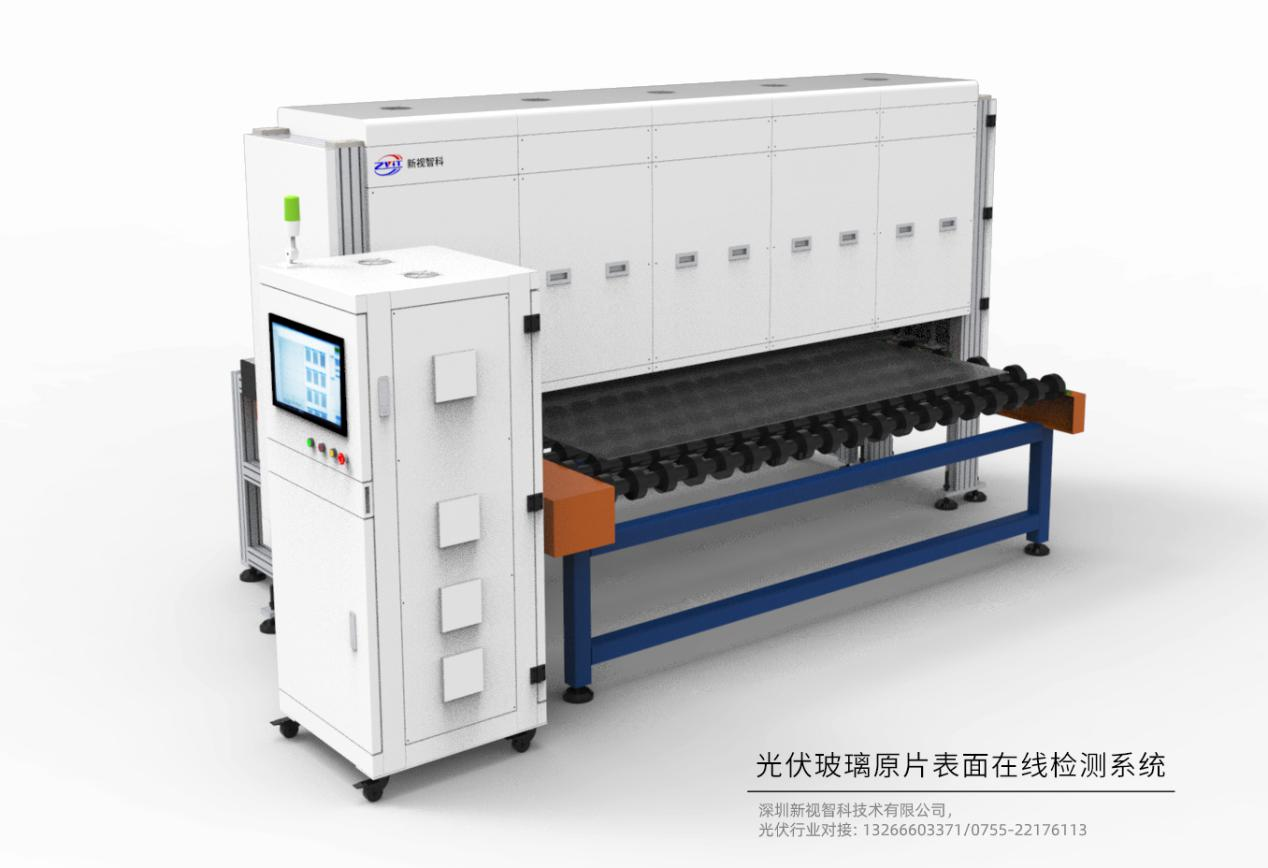

Shenzhen New Vision Technology Co., Ltd. focuses on the development and research of machine vision technology and related intelligent equipment, and has developed an online detection system for the surface quality detection of photovoltaic glass.

Photovoltaic glass glass surface online detection system is a new visual intelligence division (ZVIT) for pv manufacturers produce photovoltaic glass quality an online testing system has high precision, which is developed for the pieces after the photovoltaic glass, glass through the detection system, dust removal mechanism and marking machine, it can automatically detect the quality situation in the process of photovoltaic glass production, And the photovoltaic glass quality data statistics analysis, help the user to carry on the improvement of production process optimization, as well as the running state of real-time monitoring equipment, abnormal events timely alarm, let users grasp the production situation at any time, solve the production process of detecting link artificial cost is high, the difficulty is big, the yield is not stable.

Working principle of on-line detection system for photovoltaic glass surface

ZVIT photovoltaic glass raw surface online detection system is mainly composed of the following parts:

• Light source: contains 1 transmission light source and 2 reflection light sources, respectively, to produce transmitted light and 2 different angles of reflected light.

• Camera and lens: Receive the three-channel light generated by the light source and image the detection surface. Generally, 8K and above linear array cameras are used.

• Server: The central hub, which is responsible for defect detection and classification of the collected images, is the processing center of the entire equipment.

• Dustproof device: photovoltaic glass production workshop dust is large, increase the device to minimize dust interference.

• Visual cabinet: install and build online detection environment, and protect visual components.

• Marking device: ink-jet mark the detected defects of the testing equipment, and different defects can be marked into different marks.

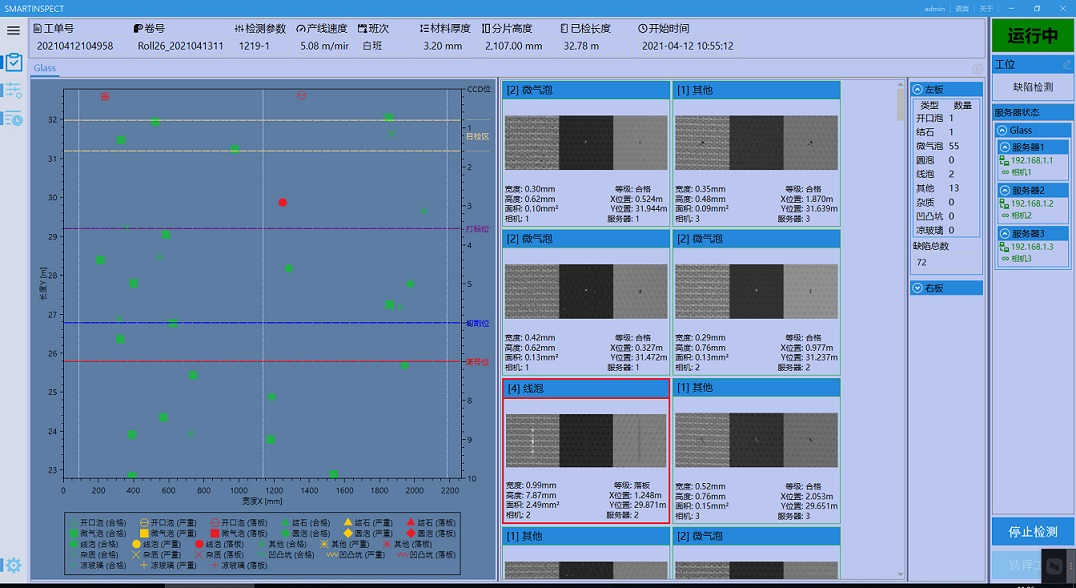

The key components of the on-line detection system for photovoltaic glass surface are camera and light source module. The lens can judge the defects according to the different shape characteristics of the images after the light source irradiates the defects. The transmission light source is mainly used to detect defects such as bubbles, stones and scratches, while the reflection light source is mainly used to detect defects on the surface of glass, such as open bubbles, roll wounds, concave and convex defects, etc. The above two light sources are identified according to the change of light path.

In the actual production process, the main performance indicators of the photovoltaic glass surface on-line detection equipment include error detection rate, omission detection rate and stability. The on-line detection system of PV glass original sheet surface can realize the effective detection of W>0.3mm, the detection speed can be up to 45m/min, the error detection rate and the omission rate are less than 1%, and the stable working time of the system can reach more than three months, leading the industry.

System advantages:

•W>0.3mm effective detection of defects, high detection accuracy;

• Multi-light source stroboscopic control, multi-angle human eye simulation, multi-spectral imaging design, multi-channel image analysis, effectively improve the detection rate;

• Leading dust identification design, through physical design, optical design, combined with self-research algorithm, matrix defect mapping logic implementation, effectively reduce the false detection rate;

• Multi-dimensional defect data analysis of the problems exposed in each stage of the process, to help customers optimize the process, and gradually improve the product yield;

• On-site intelligent Kanban board, on-site feedback problems, convenient for the team to deal with in time, while remote real-time monitoring;

• Combined with industrial Internet and 5G technology, it is easy to upgrade intelligently in the late stage and maintain the leading solution;

• Optional marking machine, quick positioning and marking defects, easy to manual maintenance;

• High cost performance, the price is much lower than foreign manufacturers, and 7X24 hours service.

Under the background that the whole world is committed to the development of clean energy, photovoltaic power generation is booming. With the market demand of photovoltaic glass and the increase of photovoltaic installation, the demand for photovoltaic glass surface on-line detection equipment is also increasing, and higher requirements for detection technology and precision are put forward.

Following the development of the photovoltaic market and customer needs, New See Smart Group always adheres to customer-centric, innovation-driven, and continues to provide customers in the photovoltaic industry with high-quality and innovative online detection solutions for photovoltaic glass surfaces, helping enterprises improve efficiency, improve quality, reduce costs and create greater value for customers.